What’s going on in the last mile?

What’s going on in the last mile? A look at how Kroger, Target, and Home Depot are adjusting their supply chains to meet customers’ omni-channel

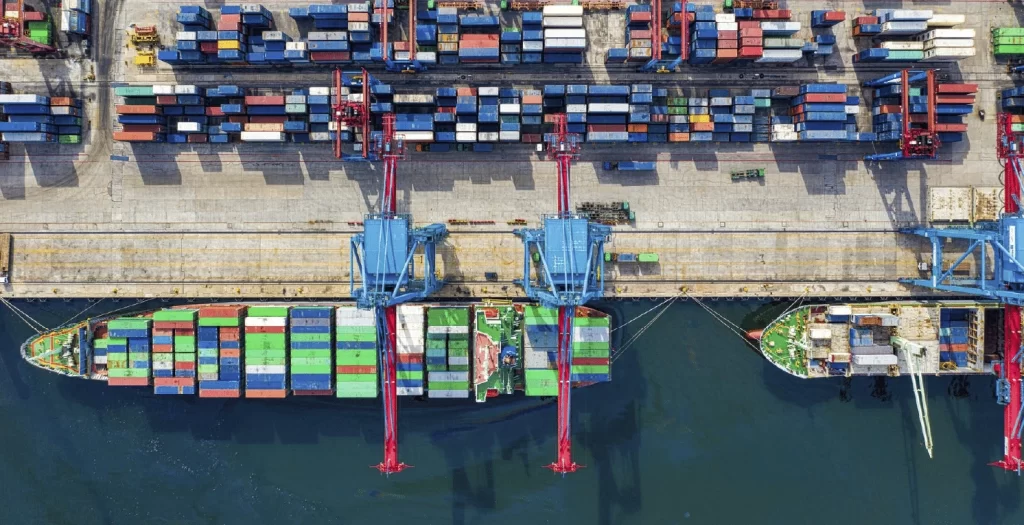

While it may come as no surprise, we primarily have COVID-19 to blame for the current global supply chain crisis. The problem is not to do with a lack of supplies, but rather, a lack of resources.

Plant shutdowns, port closures, and labor shortages within distribution facilities and the transportation industry have all contributed to the bottleneck around getting products from point A to point B. Likewise, due to the lack of resources, the cost of shipping goods has skyrocketed. According to Forbes, if it used to cost $3,000 to ship a container from southern China to the west coast of the USA, it would now cost $20,000 or more. That’s a hefty price that not many retailers can swallow.

So, how do retailers get around this problem?

Offer new-hires incentives like bonus promises, scholarships, and paid time off benefits.

If your inventory is arriving late, hold any products that will still be relevant for next season or sell it off to a markdown retailer.

* If you are interested in learning more about the 567% increase in shipping costs, check out the Forbes article: Dear Santa, You Better Watch Out: Christmas Starts Now.

Cognira is the leading artificial intelligence solutions provider for retailers. Cognira is passionate about helping retailers unlock valuable, transformative business insights from their data.

We know retail. We love data.

To learn more, check out our website at cognira.com or contact us today to get started.

What’s going on in the last mile? A look at how Kroger, Target, and Home Depot are adjusting their supply chains to meet customers’ omni-channel

Efficient customer order routing Overview Efficient and reliable routing of customer orders is critical in today’s retailing environment. Even in one of the largest and

Founded by experienced data scientists and retail experts, Cognira is the leading artificial intelligence solutions provider.