Overview

Efficient and reliable routing of customer orders is critical in today’s retailing environment. Even in one of the largest and most efficient supply networks, Amazon, shipment costs are 14% of retail sales. That’s a big number, and for most retailers who are not at the scale of Amazon, those costs are even higher. With 42% of retailers saying faster shipping is a top priority, these cost are set to go even higher. As part of our series on the cutting edge of omni-channel fulfillment, we’ll take a look at how changing from a myopic view to a more complete picture can increase the efficiency of order routing decisions.

Current state of the world when it comes to order routing

While there is great variability in order routing techniques, most boil down to applying a set of rules to determine the inventory eligible to use and then selecting the sourcing location with either the lowest shipment cost or shortest delivery time. These decisions are made one order at a time, but the challenge is we don’t just have that one order. We will have a whole set of orders coming and by ignoring these future orders, we’ll make decisions that could increase our cost and/or impact the quality of service for our most important customers.

Example

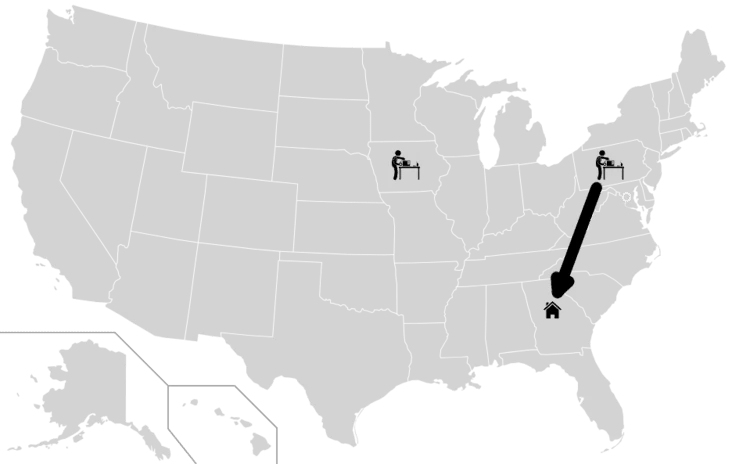

Assume we have two fulfillment centers – one in Elizabethtown, PA and the other in Cedar Rapids, IA. The Elizabethtown DC only has 1 unit on hand while Cedar Rapids, IA has 10 units. An order for standard 4 day delivery comes in from a customer in Atlanta, GA. The delivery time from both DCs with UPS Ground is 2 days, but Elizabethtown is slightly less expensive at a cost of $10.26 vs. $10.80 at Cedar Rapids. So, the order is routed to the Elizabethtown DC.

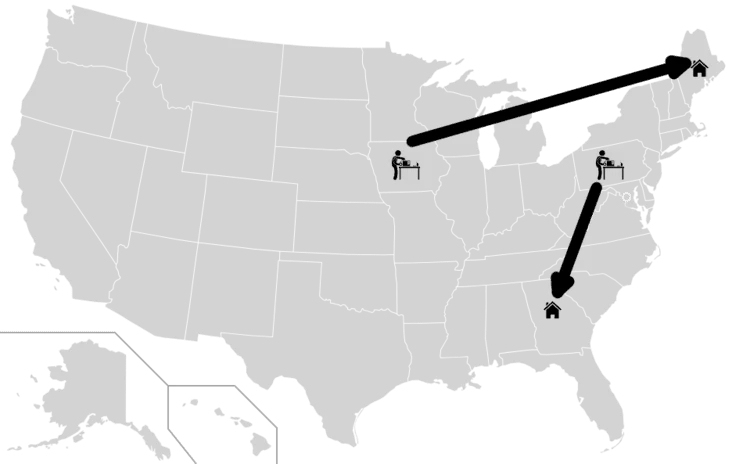

Then, another order comes in for the same product from a customer in Bangor, ME, but, she wants next day service. Since inventory is only available from Cedar Rapids, it’s shipped from there via Next Day Air from there at a cost of $65.76.

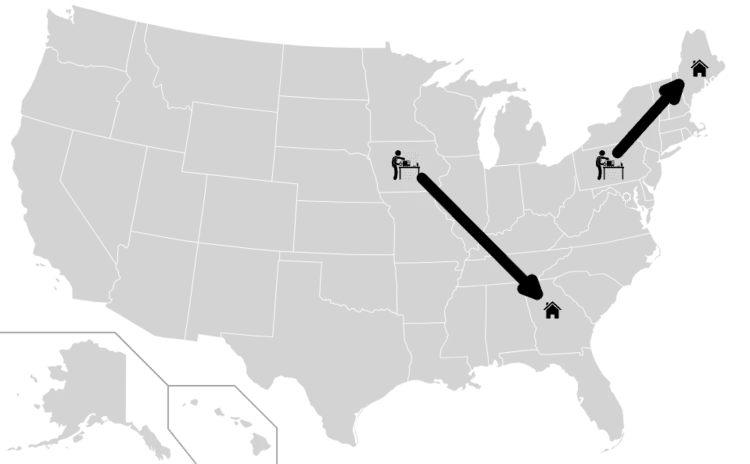

However, with perfect foresight, the most cost effective strategy would have been to ship the first order from Cedar Rapids, and the next day delivery from Elizabethtown. The total cost to fulfill both orders, $40.55, would have been 45% less than the short sighted solution.

The cutting edge of the order routing

Of course it’s not possible to know exactly where every future order will come from and the real life scenarios are much more complicated. However, it is possible to forecast the location of customer demand and incorporate the impact to the fulfillment costs into the decision of how to route an individual order. So, how can we do it?

First

A forecast of the demand by zip code and the customer’s desired service level (i.e. next day, 2 day, 4 day, whenever) is needed. While it sounds easy, it’s really hard to create a good forecast at that level of granularity, and, it often requires grouping zip codes together so that an accurate forecast can be created. Not only do we need the one number forecast, we also need the chances that we sell 0, 1, 2, or more units in each zip code, ie: the distribution of demand. This enables finding the decision that achieves your goal over all the possible demand outcomes, instead of assuming that a specific pattern is going to occur.

Next

The financial impact, including to future orders, of fulfilling a specific order from a specific location can be calculated utilizing linear programing techniques. Alright, that’s nerdy…But, it’s just a way to search through tons of possible answers and find the one that delivers the best result. One of the neat things of doing this is it can produce the expected value of having one more or less unit of inventory at a location. That’s the key value we need to understand the impact of selecting the order from that location!

Finally

As an added bonus, the forecast used by the DOM solution can also be used by the replenishment solution to ensure that inventory is located in the right place from the get go.

Credit

This work is inspired by Jason Acimovic and Stephen C. Graves’s Making Better Fulfillment Decisions on the Fly in an Online Retail Environment.